Patented

Non - flammable

Composites

Management system as per

Management system as perPN-EN ISO 9001:2015

Design Adding power to your projects

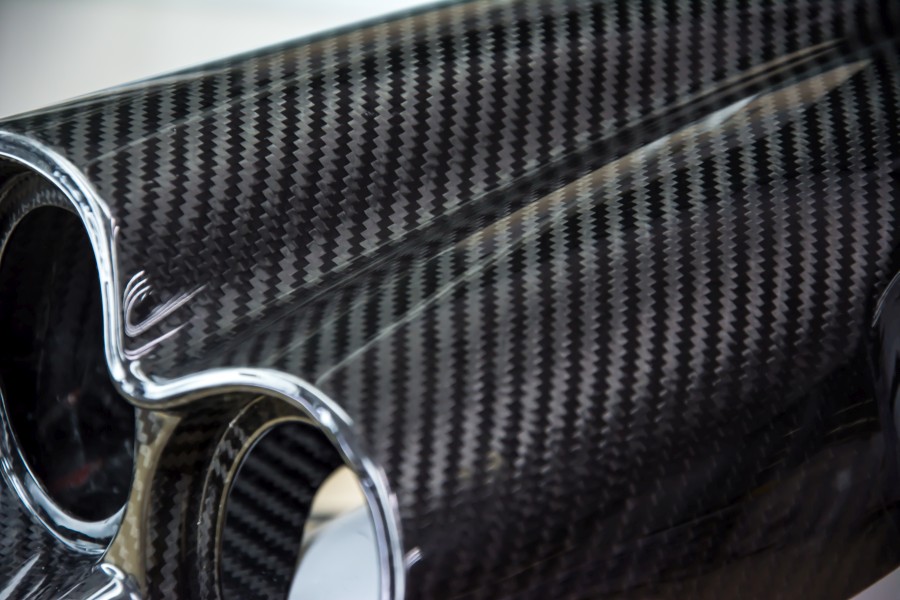

Our clients include leading motorsport industry brands competing in Formula 1, WEC, WRC, DTM and Customer Motorsport. We’ve built our business on meeting their uncompromising approach to engineering, design, quality consistency and timelines. Hexja’s agility, expertise and creativity enable us to deliver on highly complex and nuanced engineering challenges, rapidly and accurately.

How we work?

We use Dassault Systèmes’ leading edge CATIA software in the creation of composite concepts, projects, simulations, tool & pattern design and technical drawings. CATIA transforms the notion of traditional 3D CAD into Cognitive Augmented Design, fusing modeling and simulation into a single discipline. It enables Hexja to minimize errors while maximizing our freedom to innovate and experiment as designers and engineers.

Business and R&D - a winning combination

We work closely with the leading R&D centers in our industry. The results of their research and test protocols guide us and help us arrive at answers to the needs our customers come to us with.

Analysis and calculations

With access to high-performance equipment, our chassis calculation specialists maximize the performance of composites, keeping weight to a minimum. We simulate multi-body models, both in static and dynamic versions, ensuring all modeling accounts for real-world conditions.

Light, strong and fast

Our clients do not have to choose between precision execution and quick implementation of projects. In designing composites for the automotive industry, we cover every detail. Our production technology ensures efficiency of operation and the creation of products maintaining consistent, repeatable quality. Our goal: To minimize weight while maximizing performance properties. When you win, we win.

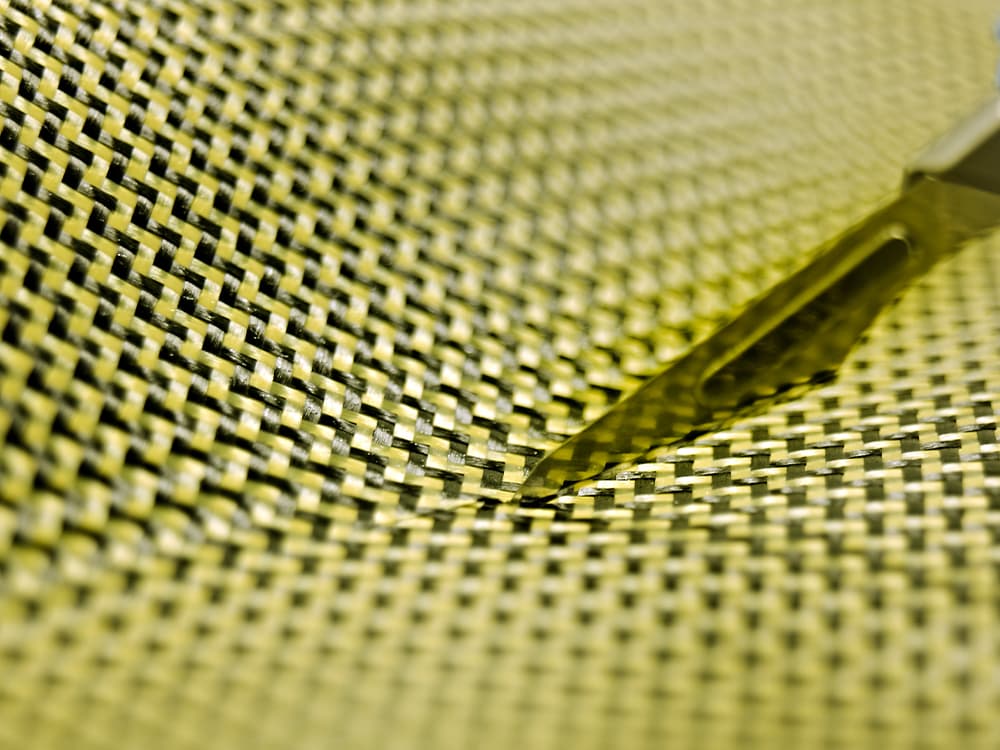

Flame-retardant carbon composite: A game-changing safety innovation

Hexja’s patented functionalized flame-retardant carbon composite (FRCC) combines the highest mechanical parameters of composites with non-flammable, no-smoke characteristics. In the event of, say, a vehicular fire, the source of flame can be more readily located and extinguished, minimizing risk to life and material damage. Hexja FRCC has been awarded UL94 V-0, the highest flammability rating assigned by Underwriters Laboratories of the United States.

The high-performance material the world has been waiting for.

Hexja has responded to a vital need within the automotive sector. Our clients can now provide their racing teams with the industry’s highest fire safety protections in high-temperature conditions and crash situations.

Intensive research and development, and our many years of experience in the field of advanced composites have enabled us to create a product line that meets or exceeds the expectations of the most demanding customer base on earth.

Even a high-temperature blowtorch can’t make Hexja’s FRCC combust, smoke or release toxic fumes and gasses.

How our flame-retardant carbon composite was developed

We applied expertise in nanotechnology to create this remarkable new material. It allowed Hexja to functionalize surfaces exposed to high temperatures or fire. When subjected to a heat source, the oxygen supply to underlying materials is immediately cut off and combustion cannot occur. All mechanical parameters of the composite remain unchanged, and the component itself is neither destroyed nor damaged by fire. An additional benefit is the non-toxic nature of FRCC. Before, during and after exposure to combustion, it remains harmless to humans and the environment.

To minimize the effects of FRCC application on the structural properties of a carbon composite part, we modify it locally, such that its non-flammable properties are strongest where it is most likely to be exposed to fire.

New possibilities for carbon composites

Where else can this technology be applied? Anywhere the use of composite carbon materials was previously impossible due to vulnerability to fire. We see this technology moving far beyond the automotive industry, in particular to companies in aerospace, medical and sports seeking more durable, safe and functional products.

We make your conceptsa reality

Our proven, up-to-date production equipment enables the development and perfection of robust products for customers who refuse to compromise.

Our laminators bring journeyman-level experience to the production of a wide range of component products for motorsports leaders. Before leaving our factory, all parts are thoroughly tested, ensuring they meet specifications, as well as performance and durability standards.

Our key technical partners

1x2m Autoclave

2x3m Autoclave

Infrastructure and Cooling Systems

NC Cutter

Ultrasonic homogenizer (sonicator)

Production Always in TOP Gear

We design, test and implement through all stages of composite creation. We can help you shorten lead-times to market on new product introductions. At Hexja, speed is everything. We deliver ready-made composite parts, instructions for laying-up materials, machining services, as well as comprehensive design and manufacture of carbon fiber molds for the automotive industry.

Our team has over 15 years’ experience in the composites industry and over 10 years in the design and manufacture of premium components for clients at the pinnacle of motorsports – Formula 1, WEC, WRC, DTM and Customer Motorsport.

Essential body panels:

- Wings

- Side pods

- Engine covers

- Diffusers

- Splitters

Complex structural components

- Monocoques

- Chassis

- Pillars

- Nose boxes

Hexja launches with an edge in location, talent and equipment.

Why Hexja? Our clients come to us for creative design and manufacturing, and to ensure their products are superior to all others. Our team of experts love to create, innovate and transform smart ideas into the solutions you need. Modern equipment and a strategic location enable Hexja to offer clients competitive pricing along with a fluid and collaborative working relationship.

Respond more rapidly to changing market conditions

We cut our teeth on projects for automotive and motorsport clients, an uncompromising customer base. What counts for them is collaboration cooperation, a flexible approach to change and the highest quality at a fair price. Hexja goes beyond merely providing what our customers need; we’re always looking a few steps ahead at innovations they haven’t yet considered.

What’s your challenge?

Launching in 2010, we built a brand that’s now widely recognized in the automotive industry, thanks to the determination, talent and experience of our team.

We don’t limit ourselves to what we already know. We develop new products and applications for composites in our daily research, in our laboratories and in rigorous testing.

Right where you need us

Part of Hexja’s competitive advantage is our location. We design and manufacture our entire high-performance product line in wholly-owned facilities in Oświęcim, Poland. A vibrant city, it boasts ever-improving infrastructure and is well connected to the rest of the country. Two international airports, in Krakow and Pyrzowice/Katowice, are only 40 minutes’ drive from our headquarters, providing rapid access to raw materials and next-day shipping within the EU.

This powerful blend of location and expertise means winning products, pricing and delivery times to happy customers all over the world.

Contact

Facing down an impossible challenge?

Talk to us. We eat limitations for lunch!

HEXJA Composites Sp. z o.o. Sp. K.

Gospodarcza 4, 32-600 Oświęcim, PL

REGON: 364421892, NIP: 5492444299, KRS: 0000616771